In the globe of electronics and modern technology, the importance of printed circuit boards (PCBs) can not be overstated. A PCB, commonly referred to as a circuit board, supplies the essential framework for connecting various electronic components through conductive tracks etched onto non-conductive substratums. Amongst the several types of PCBs, the rigid-flex circuit boards stand out as a remarkable development.

The production of PCBs, especially in high-density interconnect (HDI) arrangements, has evolved as the need for smaller, quicker, and more effective electronics rises. HDI PCBs incorporate finer lines and areas, as well as smaller sized vias, which allow for better element density.

Collective ventures with printed circuit manufacturers are vital in guaranteeing that PCB styles transition smoothly from theoretical stages to real items. These manufacturers focus on numerous aspects, including PCB assembly and fabrication. They make use of products like FR-4, a flame-retardant epoxy material, which is extensively concerned for its equilibrium of efficiency and cost-effectiveness. In the realm of high-performance applications, variations such as Rogers material, Megtron 6, and Megtron 7 are regularly used for their exceptional dielectric residential or commercial properties and high-frequency efficiency. Printed circuit board assembly (PCBA) comes to be an essential action in the process where various components are soldered onto the PCB in precise arrangements to guarantee ideal procedure.

Quick turnaround PCB prototyping services have actually obtained popularity as companies aim to bring their items to market swiftly. With the increasing availability of fast-turn PCB services, the barriers to prototype advancement have actually been dramatically lowered, enabling an atmosphere of advancement.

Flexible printed circuit boards (FPCBs) are an additional exceptional category that has actually garnered focus due to their one-of-a-kind abilities. These boards are developed to be lightweight and ultra-thin, providing the ability to flex, fold, or spin without jeopardizing performance.

Thermal management, for instance, plays an important duty in PCB design, specifically in electronic items that run under high lots. Engineers must consider materials with great thermal conductivity, such as heavy copper PCBs, which assist dissipate warm successfully.

Understanding regarding various facets such as circuit card assembly, which consists of the process of soldering read more components onto a PCB, can dramatically affect the end item's top quality. Additionally, making use of tools and software created for PCB layout and simulation can dramatically enhance the design process, allowing designers to quickly change prototypes based on testing results.

Variants in PCB types such as 2-layer, 4-layer, and multi-layer boards are each matched to particular applications based upon their intricacy and the number of parts that need to be incorporated. Four-layer PCBs give enhanced transmitting capabilities, important for extra sophisticated electronics. These boards assist in taking care of signal integrity and offer enough space to route traces a lot more successfully, ensuring more trustworthy performance in everything from mobile phones to complicated commercial tools.

Contract PCB assembly services have actually become an important resource for companies lacking the internal abilities to take care of intricate assembly procedures. These services often include detailed assistance varying from design appointment to full-scale production, providing businesses with the flexibility they need to fulfill differing needs. By partnering with well-known manufacturers, organizations can utilize experience in locations such as HDI formats, microvias, and multilayer PCBs, consequently broadening their product offerings without investing greatly in tools and labor.

Picking the ideal materials for PCB production is essential, and considerations often consist of the environmental standards applicable to their usage, including UL ratings, such as 94V-0, which relates to terminate retardancy. Manufacturers need to remain educated regarding compliance regulations to guarantee that their products fulfill security standards while additionally carrying out optimally in their desired application atmospheres.

The assimilation of radio frequency (RF) technology right into PCBs is another area seeing raised significance, specifically with the increase of cordless communication tools. RF PCBs have to be very carefully developed, with factors to consider for impedance control and lessened signal loss due to the high frequencies entailed. This specialization needs expertise of RF circuit design and may include thorough electromagnetic simulations as designers function to achieve ideal capability in compact kinds.

As innovation remains to progress, manufacturers are significantly adopting automation and advanced fabrication procedures to boost efficiency. Technologies such as automated optical evaluation (AOI) and surface install read more modern technology (SMT) are currently standard practices, enabling high-speed assembly and constant quality assurance. Innovations in PCB manufacturing also extend to new products and strategies, such as using embedded technology where components are embedded directly within the layers of the PCB, even more saving space and improving performance.

Whether through PCBA, flexible circuits, or fast-turn prototypes, the procedures, materials, and layouts associated with PCBs are important in forming the future of electronic devices. With the ever-increasing intricacy of circuits and the need for efficient, high-performance services, the PCB market continues to be get more info a cornerstone of technological progression, driving the means we interact with gadgets and eventually attaching our physical and digital worlds.

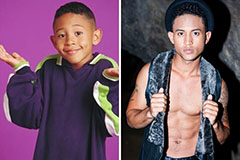

Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!